SPRAYTRONIC

The right application rate in the right places regardless of the working speed

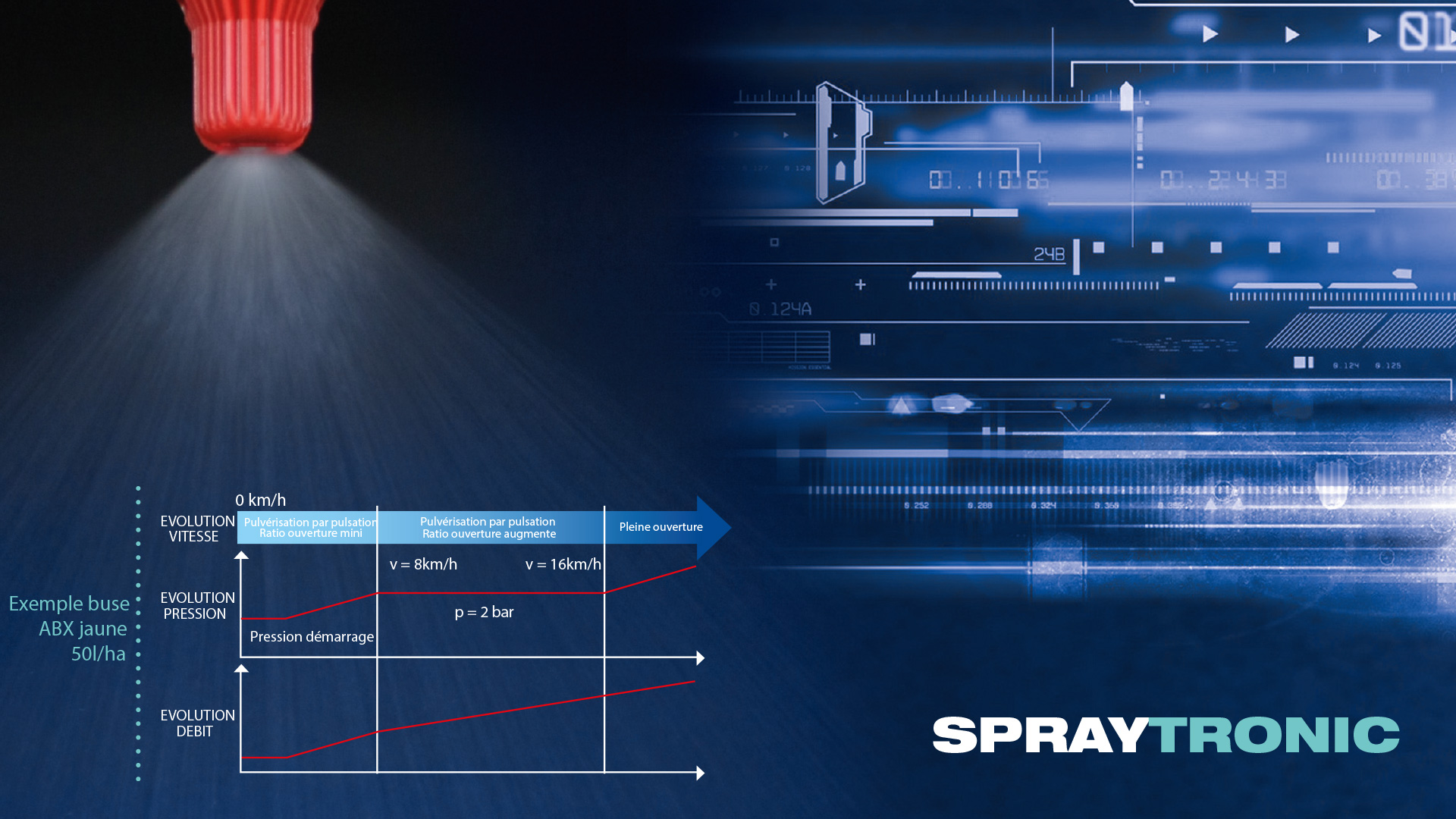

With spraying, the main problem of current systems is the limited working speed range to ensure a good spraying quality. Beyond that range, the drops are either too fine (dispersion) or too large (flow). To address this issue, BERTHOUD has developed its SPRAYTRONIC PWM (Pulse Width Modulation) spraying system. Each plant gets the exact dose it needs in the right place for perfect protection.

A flow that varies directly at nozzle level

The SPRAYTRONIC is a device that allows you to vary the flow of the mixture while preserving the pressure and thus the size of the droplets without changing the nozzle: the same 3-bar nozzle from 8 to 18 km/h.

Depending on your forward speed, a solenoid valve on

each nozzle will disperse the spray. The ratio between the opening and closing time varies depending on the speed variation at a fixed frequency. Simply put, the nozzle opens and closes 20 times per second. The spray flow is modulated by varying the opening time within an opening/closing cycle. It works on an easy-to-use principle: the user simply selects the nozzle to be used, the operating pressure and the volume per hectare.

SPRAYTRONIC thus makes it possible to vary the flow of a nozzle by 50%,

and the working speed by the same proportion, without changing the operating pressure.

The pulsating spray nozzles also stand out from other models by paving the way for nozzle-by-nozzle shut-off and modulation.

Application precision and cost reduction

- A single nozzle with a standard nozzle holder : no need to have a large number of nozzles since the SPRAYTRONIC system covers the majority of needs with a single nozzle. The nozzle operates in its optimum operating range, which limits drift.

- Nozzle-by-nozzle shut-off prevents overlap and overdosing, which reduces the use of plant protection products.

- Compensation at bends for an even application : avoids

overlapping, overdosing or underdosing.

- Optimum application quality : no pressure jumps due to nozzle changes and option to control the function by entering a desired operating pressure. The pressure is constant regardless of the working speed. No more compromise between working speed and spraying quality.